On September 26, 2011 the representatives from “Yo-auto” and “SWEL energy” carried out joint testing of a special electronic device, designed by “SWEL energy” and intended for reduction of internal resistance in chemical cells during their discharge. The testing consisted of the charge of an assembly (of accumulator batteries) of 13 lead-acid accumulator batteries GP1270 (12 V/7.0 A∙h) and its subsequent discharge to constant resistive load (a thermoelement) with the electronic separator and without it. The measuring equipment (a multichannel USB-recorder) was provided by “Yo-auto”. The recorder helped to register: voltage on the assembly, discharge current of the assembly, voltage and current of the load, and also the temperature at two points on the surface of accumulator batteries.

Major testing characteristics

| Parameter | Value | Comments |

| Maximum charge voltage of the assembly | 174 V |

The value - 2.23 V per accumulator (6?2.23=13.38 V per battery GP1270) - was chosen deliberately in order to minimize energy losses due to gassing in the lead accumulator during its charge |

| Initial charging current | 3.9 А |

Final finishing rate of the assembly - 0.3 А |

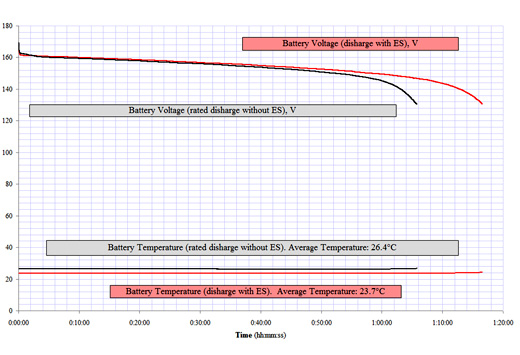

| Initial and final temperature of the assembly during the first discharge cycle | 23.75/24.2°С |

Temperature on the surface of the assembly (average value from two sensors) - discharge through the electronic separator |

| Initial and final temperature of the assembly during the second discharge cycle | 26.6/26.7°С |

Temperature on the surface of the assembly (average value from two sensors) - discharge without electronic separator |

| Voltage on the load | 129 V |

Constant output voltage in both assembly discharge modes |

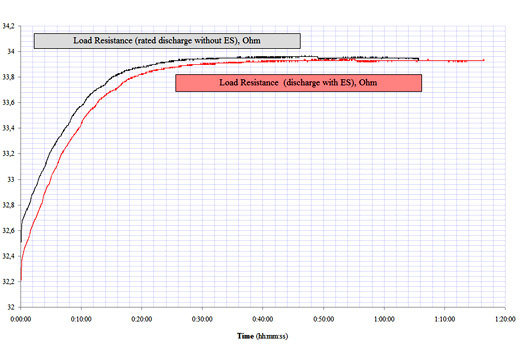

| Load resistance | 32.2 Ohm |

Initial resistance, without load heating during the tests |

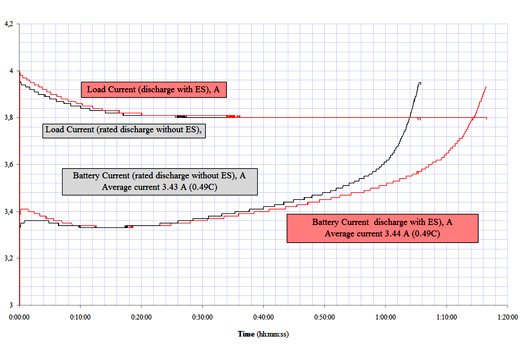

| Average load power (on the output of voltage stabilizer) | 502.5 W 498.5 W |

- during assembly discharge through the electronic separator |

| Average discharge current | 3.44 А |

About 0.5С (by assembly capacity = 7.0 А•h) |

| Assembly discharge time down to 130 V (10 V / per battery GP1270) | 76.57 min. 65.75 min. |

- during discharge through the electronic separator |

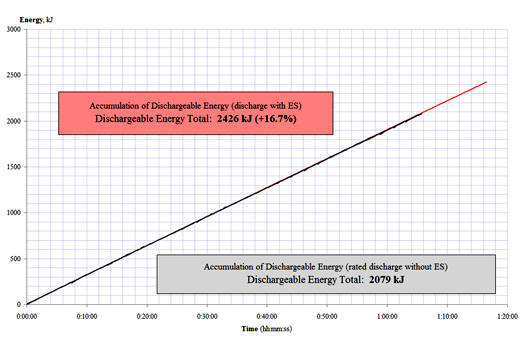

| Energy transferred by the assembly during discharge | 2426 kJ 2079 kJ |

- during discharge through the electronic separator |

Test results

The testing of "SWEL Energy" electronic separator gave the following results:

- When the electronic separator is connected, the discharge time of the assembly of 13 lead-acid accumulator batteries GP1270 (12 V / 7.0 А∙h) discharged by the current 0.5 C from 174 V voltage (13.38 V per battery) down to 130 V (10 V per battery) increases by 16.45% in comparison with a common discharge mode;

- The energy extracted from the accumulator battery during its discharge through the electronic separator, grows by 16.67% in comparison with a common discharge mode.

- The assembly discharge was conducted at considerably lower (by 2.5 – 3ºC) accumulator temperature than in a common discharge mode. Considering high (up to 3% / ºC) steepness of lead-acid accumulator efficiency – temperature curve, the total increase of power extracted from the accumulator, reaches 25%.

Appendixes:

- Comparative time dependencies of various parameters during assembly discharge through electronic separator (ES) and without it (Fig. 1-4);

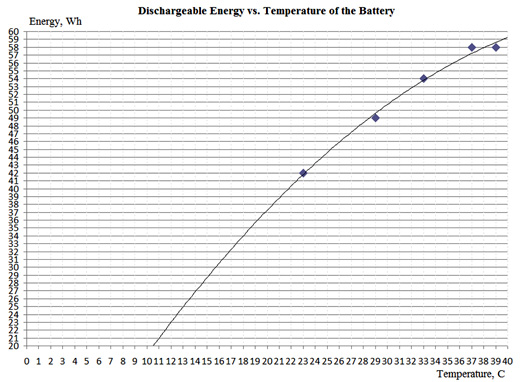

- Energy extracted during assembly discharge – temperature dependence (Fig.5).